What is Stirling engine?

A Stirling engine converts heat into mechanical energy by compressing and expanding air or gas at different temperatures in a cycle. This process allows the engine to produce work. The engine operates by using heat to move the air or gas back and forth. The movement of the air or gas creates mechanical energy that can be used for various purposes.

To be more precise, the Stirling engine is a permanently gaseous closed-cycle regenerative heat engine. In this situation, "closed-cycle" means the fluid stays inside. "Regenerative" means using a special temperature exchanger called a regenerator. What sets a Stirling engine apart from other closed-cycle heat engines is the presence of a regenerator.

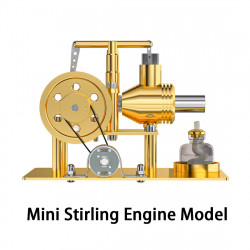

The Stirling engine generator is a striking, charging, and eye-catching piece of communication equipment around your workplace. Seeing people's reactions and expressions as they smash something that went for this Stirling engine kit is fascinating.It can edify the bulb and run like nothing else if you only ignite the liquor burner, let it warm the chamber for a few seconds, and then gently push the wheel. The number of people who must acknowledge what happened is an icebreaker. What a wonderful toy! It has been shown to be a well-planned interaction that will surprise your guests. The Stirling engine model, which even stands outside your work area, is a neat piece of craftsmanship.

The goal of a Stirling engine is to provide a net difference in thermal energy to mechanical work by using the cyclic weight and improvement of air or another gas at different temperatures. The functioning theory is comparable to an inside turnover motor because the heat capacity created by the consuming liquor light allows the gas to extend inside. At that point, the gas atomic inner force is stretching out and unmistakably working to the flywheel. Heat energy will be converted into mechanical work with the help of the flywheels.

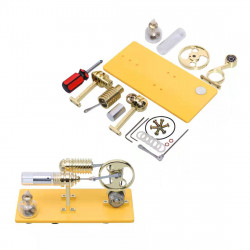

Our stirling engines for sale are an excellent educational tool that can be used in a lab or classroom to initiate the ideal situation for teens in material science. They are fairly basic, but make excellent gifts for friends or family.

Our kits also have a cool shape, which is the perfect combination of a stirring engine and a magnificent vehicle. They look amazing and unique, cruel and eye-catching, and are brimming with mechanical and creative sense. They also have heavenly first-in-class accuracy metal distinguishing strengths, dazzling work and area model embellishments, and very assortment respect. where the craftsmanship is astounding, the surface is expertly handled, smooth, astounding, and brimming with beauty, comprehending the dual fusion of surface and meaning.

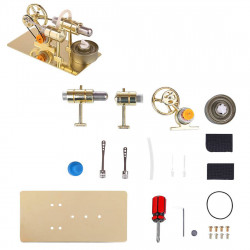

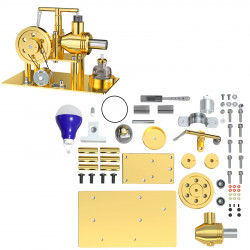

Given the homemade nature of the Stirling Engine DIY, you should suggest a joint get-together heading to draw in DIY enthusiasts. View the gathered model on a flat surface, warm the hot chamber with a liquor light, and create dry air to transfer power to the model. By assembling the model yourself, exercise as much as you can, observe the model's activity example, and comprehend its rules and structure. To increase your knowledge of material science and your learning capacity, you can conduct systematic and mechanical exploratory demonstrations. It can also be used to give loved ones a wonderful, flawless gift for special occasions.

You should not use various oils when utilizing it, and you should set up the liquor fuel alone. If it's not too much difficulty, let the engine cool down after using it. Try to avoid coming into contact with the metal, the consumed chamber, or the alcohol burner to prevent scalding. In the development, 95% alcohol should be used. Alcohol, gas, lighter oil, water, and light fuel should not be added. Additionally, the Stirling motor model is appropriate for those older than 14; if you are under that age, please operate under adult supervision.

What are the Uses for Stirling engines?

1, Cogeneration (CHP)- A Stirling engine in a cogeneration unit can use waste heat resulting from the second law of thermodynamics. This waste heat can power the Stirling engine for industrial or agricultural activities.

2, Solar energy generation- Stirling engines, as shown in the figure below, can convert sun power into electricity more efficiently than some photovoltaic cells when placed at the primary of a parabolic mirror.

3, Submarines- Submarines with Stirling engines have a significantly longer submersion time than regular submarines. The first submarine to use Stirling engines was built by the Swedish shipbuilder Kockums. These engines allow a submarine to submerge for more extended periods—days or even weeks—without having to surface to replenish its batteries.

Nuclear power plants: Stirling engines can replace steam turbines in nuclear reactors, improving plant efficiency and lowering the amount of radioactive byproducts. These would eliminate the need for water at any point in the cycle and replace it with liquid sodium as a coolant.

4, Educational demonstration- a slight temperature variation A stirling engine can operate at any low-temperature differential, such as the one between a hand's palm and palm, as shown in Figure 4. (A Low-Temperature Difference (LTD) Stirling engine may produce around 1 W of power directly from a person's palm.)

What is the Coffee Cup Stirling Engine?

Drinkable fuel-powered engines seem like a neat idea, don't they? To me, they most definitely are.

A cup of coffee The Stirling engine operates at low temperatures. A horizontal, circular displacer on a stirling engine that is marginally bigger than the coffee mug it is intended to rest on.

Professors I. Kolin and J. Senft made the first stirling motors in the 1980s. Professor I. Kolin was from the University of Zagreb, while Professor J. Senft was from the University of Wisconsin.

The stirling motors were created by the professors. This happened in the 1980s. Temperature changes of less than 20°C may start these motors.

The vertical flywheel of these engines is held up above the displacement by a platform.

How Coffee Cup Stirling Engine Works?

It uses the heat flow between the base plate and cover to work. The temperature differential between the plates must be sufficiently high to produce this flow.

This can happen if you heat or cool the base plate. You can use a hot cup of coffee, your hand, a receiver, a computer monitor, or other household items to preheat it. Another way to run the motor is to cool the base plate, which can be accomplished by setting it over an ice cube bowl.

It can also be utilized as a solar motor. The motor will still run when the motor's base plate is colder than the cover plate due to sun radiation heating its dark top surface.

However, the flywheel travels in the other direction, and the Stirling motor works backward when powered by ice or solar energy. To start the Stirling motor, turn the flywheel in the right direction. Make sure the motor has been on the heat or cold source for one to two minutes.

How does a Stirling engine work?

Similar to a steam engine or an internal combustion vehicle engine, a Stirling engine repeats a set of fundamental actions, or its cycle, to transform heat energy into mechanical energy (work). Let's look at a Stirling engine, a more straightforward displacer type.

The gas inside the cylinder changes size as it moves between the hot and cold sides. This can be confusing to understand.

The gas expands when it is heated and contracts when it is cooled. This process causes the gas to get bigger and smaller.

The dark blue work piston compresses the gas. This helps keep the cycle going.

It uses the energy from the gas's expansion. This energy powers the engine-driven machine.

The green displacer piston moves gas from the hot side of the cylinder to the cold side and back. The hot side is on the left, and the cold side is on the right. The two pistons work together to move heat energy from one place to another and turn it into useful mechanical work.

In detail

- Cooling and compression: The colder end of the cylinder is located on the right, where the blue squares indicate most of the gas. Both pistons move inward (toward the center) as they cool and compress, giving off some heat removed by the heat sink.

- Transfer and regeneration: The cooled gas travels around the displacer piston, which moves to the right, to the hotter section of the cylinder, which moves to the left. As the gas goes through the regenerator (heat exchanger) again, its volume stays constant as it absorbs some of the heat that it had previously deposited.

- Heating and expansion: In the hot end of the cylinder, most of the gas is now located on the left (shown by the red squares). The fire (or other heat source) heats it, causing its pressure to rise and expand to absorb energy. The work piston is forced to the right by the expanding gas, which powers the flywheel and any other engine-driven devices. The engine transforms thermal energy into mechanical energy during this portion of the cycle, and it works.

- Transfer and cooling: Hot gas travels around the displacer piston, which moves to the left, and into the more excellent section of the cylinder, which moves to the right. While the gas loses some energy while traveling through the regenerator (heat exchanger), its volume stays unchanged. Now that the cycle has finished, it is prepared to begin again.

Energy is continuously taken from the source and placed at the sink, even though the engine completes a cycle and returns to its starting point. This happens because when the hot gas expands, it pushes the working piston with a certain amount of force. However, when the cooled gas is compressed and returns to its original position, it exerts less force on the piston.

In theory

You may be thinking, "Wow, this is all pretty elaborate! A basic steam engine can function with just one piston, so why fiddle with two? Why are there so many distinct stages? Why not simplify everything altogether?"

You must comprehend the theory of engines to respond appropriately to those questions. According to the theory, a good engine moves gas through different steps using the gas laws.

These laws are basic principles in classical physics that explain how pressure, volume, and temperature are related in a gas. The most famous idealized cycle is called the Carnot cycle. The most well-known idealized cycle is the Carnot cycle.

This cycle consists of two separate phases. The first phase involves expanding the gas adiabatically (heat-conserved) and isothermally (at a constant temperature). The second phase also includes expansion that is adiabatic and isothermal.

A Stirling engine uses a different cycle that (ideally) consists of:

Isothermal (constant temperature) compression: In step (1) described above, the gas loses heat to the sink while its volume drops and pressure rises.

Isovolumetric (constant volume) heating: As the gas goes through the regenerator again and absorbs some of its lost heat, its volume stays constant. This is the scenario described in our stage (2) above.

Isothermal (constant temperature) expansion: The stage (3) described above, in which the gas absorbs energy from the source and experiences a rise in volume and fall in pressure at the same time as a constant temperature.

Isovolumetric (constant volume) cooling: As the gas passes through the regenerator and cools, its volume stays steady, as seen in our stage (4) above.

This cycle is repeated in a more complicated and less idealized form in a genuine Stirling engine, but that is outside the purview of this article. The four stages blur into one another rather than being strictly distinct from one another. If this interests you, the Stirling cycle article on Wikipedia has much more information.

Vacuum Engine VS Stirling Engine: Who Wins?

Q: Is the Vacuum Engine the same as the Stirling engine?

A: No, not at all.

Q: What's the difference? Are Vacuum Engines More Powerful than Stirling Engines?

A: A sealed cylinder with one part hot and the other cool is a feature of every Stirling engine. A mechanism transfers the working gas, often hydrogen, helium, or air, from the hot side to the cold side of the engine. The gas expands and presses up against a piston as it is heated.

Air pressure pushes against one side of a piston. This creates a force that powers a vacuum engine. The force is directed towards the vacuum on the other side of the piston. Before the subsequent outstroke starts, the valve reopens to allow the piston to release the burned gasses.

The Stirling engine is better than the vacuum engine in terms of mechanics. However, its thermal efficiency is only 15% to 30%. This is still lower than the vacuum engine.