The Working Principle of Jet Engine

The aircraft flies quickly thanks to the powerful thrust of its jet engines.

The basic idea behind how all jet engines, also known as gas turbines, operate is the same. Using a fan, the engine draws air in from the front.

The air pressure is increased using a compressor. A shaft is used to support several blades that make up the compressor. The air is compressed or squeezed by the blades' rapid spinning motion.

Fuel is subsequently sprayed into the compressed air, and an electric spark ignites the mixture. The nozzle near the engine's rear is where the expanding, burning gasses emerge. The engine propels the airplane forward as the gas jets blast rearward.

The heated air travels through the turbine, an additional set of blades, en route to the nozzle. The compressor and turbine are fixed to the same shaft. The compressor spins when the turbine spins.

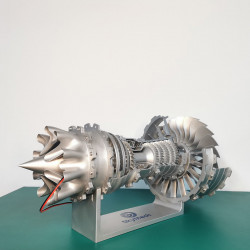

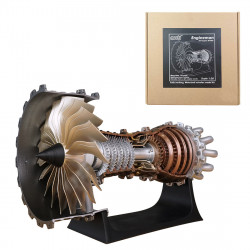

The picture below depicts the airflow through the engine. The engine's core is surrounded by air and passes through it. As a result, some areas of the air are scorching, while others get colder. The hot air mixes with the colder air at the engine exit locati0n.

What is Thrust?

Thrust is the forward force that propels the engine and, by extension, the aircraft forward. It was discovered by Sir Isaac Newton that "there is an equal and opposite reaction to every action." This idea is applied to engines.

The engine inhales a lot of air. The air slows down, heats, and compresses. Air is pushed through numerous rotating blades.

The air can reach up to 3,000 degrees when combined with jet fuel. The force of the air turns the turbine. At last, the air exits the engine and pushes backward. The plane takes off as a result.

Parts of a Jet Engine

Fan - The turbofan's fan is its first part. The massive rotating fan draws in a lot of air.

Titanium makes up the majority of the fan's blades. After that, it divides the air into two portions and accelerates it up. Proceeding through the "core" or center of the engine, one section is affected by the other parts of the engine.

The second section "bypasses" the engine's core. It travels to the back of the engine, generating most of the force that moves the aircraft forward via a duct that encircles the core. In addition to giving the engine more thrust, this colder air also helps to quiet it down.

Compressor - The engine core's first part is the compressor. The compressor is composed of multiple-bladed fans that are fixed to a shaft.

The compressor raises the air pressure by squeezing the air that enters it into increasingly smaller spaces. As a result, the air's capacity for energy increases. The combustion chamber is forced to contain the compressed air.

Combustor - Fuel and air are combined in the combustor, where they are ignited. Up to 20 nozzles are used to spray gasoline into the airstream.

Fuel and air mix and catch fire. This creates an airflow with great energy and temperature.

Burning fuel and oxygen in the compressed air produce hot, expanding gases. To make a chamber resistant to heat, the inside of the combustor is frequently constructed of ceramic materials. It can be as hot as 2700°.

Turbine - The turbine's blades rotate due to the high-energy airflow entering it from the combustor. A shaft connects the turbines, which rotate the compressor's blades with the front intake fan. This spin partially consumes the high-energy flow that powers the compressor and fan.

The turbine's blades rotate due to the combustion chamber's gasses passing past it. The jet's turbines rotate hundreds of times. They are fixed on shafts with many ball-bearing sets spaced apart.

Nozzle - The engine's exhaust duct is the nozzle. This engine component is what gives the aircraft its thrust. When the nozzle closes, colder air bypasses the engine core.

The energy-depleted airflow goes through the turbine. These two airflows come together to generate a force. This force propels the engine and the aircraft forward.

A forward thrust is produced when the hot and cold air combine to form an exhaust and are released. Before the nozzle, the mixer could mix the hot air from the engine core with the colder air from the unused fan. The mixer contributes to the engine's reduced noise.

Who Invested The First Jet Engine - A Short History of Early Engines

Sir Isaac Newton introduced the concept of a machine moving rapidly by using an explosion directed backwards in the 18th century. This concept involved a machine traveling at high speeds.

The machine would be propelled by an explosion channeled in a rearward direction. This notion was based on his third law of motion. The plane flies forward and backward as the hot air explodes through the nozzle.

The first aviation engine, a three-horsepower steam engine, was used by Henri Giffard to propel his airship. It was too heavy to take into the air.

Felix de Temple used a coal-fired steam engine in 1874 to build a monoplane that could only make a short hop down a hill.

In the late 1800s, Otto Daimler created the first gasoline-powered engine.

American Hiram Maxim attempted to use two coal-fired steam engines to propel his triple biplane in 1894. It took only a few seconds to fly.

Heated coal was used to power the early steam engines, which were typically far too heavy to fly.

American Samuel Langley created steam-powered model airplanes. He successfully piloted the Aerodrome, an uncrewed aircraft with a steam engine, in 1896.

Before it ran out of steam, it flew about a mile. Subsequently, he attempted to construct the Aerodrome A, a large aircraft with a gas engine. It was launched from a houseboat in 1903 and crashed right away.

The Flyer, propelled by a gas engine with 12 horsepower, was piloted by the Wright Brothers in 1903.

From 1903 to the late 1930s, airplanes were only powered by gas-powered engines with propellers. The Wright Brothers made the first flight in 1903. The engines used were reciprocating internal combustion engines. These engines were the only source of power for aircraft during this time period.

In 1930, British pilot Frank Whittle created and received a patent for the first turbojet engine. In May 1941, the Whittle engine made its maiden successful flight. This engine included a combustion chamber, a single-stage turbine, a nozzle, and a multistage compressor.

Hans von Ohain was developing a comparable concept in Germany concurrently with Whittle's work in England. The German Heinkel He 178 became the first aircraft to operate a gas turbine engine successfully in August 1939. It was the first turbojet-powered flight in history.

General Electric produced the first American jet engine for a US Army Air Force aircraft. The experimental aircraft that made its maiden flight in October 1942 was the XP-59A.

Types of Jet Engines

Turbojets

The turbojet engine's core concept is straightforward. In the compressor, air that enters through a hole in the front of the engine is compressed three to twelve times its initial pressure. Fuel is added to the air and burned in a combustion chamber to raise the temperature of the fluid mixture. The temperatures reached are between 1,100°F and 1,300°F.

The compressor is powered by the hot air produced after it passes a turbine. When a turbine and compressor work well, the pressure at the turbine discharge will be almost double that of the surrounding air. This extra pressure is directed toward the nozzle, creating a thrust-producing high-velocity gas stream.

Using an afterburner can result in significant gains in thrust. A second combustion chamber is situated in front of the nozzle and after the turbine.

The gas in front of the nozzle gets hotter thanks to the afterburner. The rise in temperature increases the thrust by 40% during takeoff. The thrust increases even more at high speeds once the aircraft is in the air.

An example of a response engine is the turbojet. Expanding gasses in a reaction engine exert significant pressure on the engine's front.

The air is drawn in by the turbojet and compressed or squeezed. The turbine rotates because of the gases that pass past it. These gases propel the plane forward as they fly out of the exhaust's back and bounce back.

Turboprops

A jet engine coupled to a propeller is called a turboprop engine. The heated gasses in the back drive a turbine, turning a shaft that powers the propeller. Turboprop engines are used to power a few small carriers and transport planes.

Like a turbojet engine, a turboprop engine comprises a compressor, combustion chamber, and turbine. The turbine is powered by the air and gas pressure, which also powers the compressor. At flying speeds lower than roughly 500 miles per hour, the turboprop engine performs more efficiently in propulsion than a turbojet engine.

New turboprop engines have propellers with more blades, even though they are smaller. This helps them work better at higher speeds." The blades are fashioned like a scimitar, with swept-back leading edges at the tips for increased flying speeds.

Turbofans Jet Engine

A big fan on the front of a turbofan engine draws air in. Most airflow passes around the engine's outside, which reduces noise and increases thrust at low speeds.

Nowadays, turbofans power the majority of airplanes. The compressor, combustion chamber, and turbine that make up the gas generator process all of the air that enters the intake of a turbojet. Just a fraction of the incoming air enters the combustion chamber of a turbofan engine. The remaining material is combined with the gas generator exhaust to create a "hot" jet or is ejected directly as a "cold" jet after passing via a fan or low-pressure compressor.

This kind of bypass system aims to boost thrust without adding more fuel. It accomplishes this by lowering the velocity and raising the overall air mass flow within the same total energy source.

Turboshafts

This is an additional type of gas turbine engine that functions similarly to a turboprop. It is not a propeller driver. Instead, it powers the rotor of a helicopter.

The turboshaft engine's architecture determines the speed of the helicopter rotor, not the rotational speed of the gas generator. This enables the rotor speed to remain constant even when the generator speed is adjusted to adjust the power output.

Ramjets

The ramjet, which has no moving parts, is the most basic type of jet engine. The jet's velocity "rams" or "forces" air into the engine.

It is simply a turbojet without any rotating machinery. Its compression ratio depends entirely on forward speed, which limits its application. Below the speed of sound, the ramjet produces relatively little push overall and no static thrust.

A ramjet vehicle, therefore, needs assistance during takeoff, such as from another aircraft. It has mainly been applied to guided missile systems. This kind of jet is used in spacecraft.